- 900 Grossman Drive Schofield, WI

- Take a Virtual Tour

- sales@norlen.com

- 800-648-6594

- Index

- / Departments

- / Metal Stamping & Tooling

Metal Stamping & Tooling

- Home /

- Departments /

- Metal Stamping & Tooling

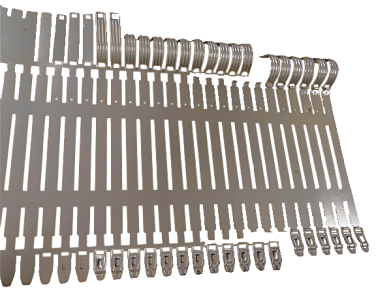

Metal Stamping

With world class press lines and the expertise to maximize efficiencies, Norlen combines the design, tool build, production, and preventive maintenance program to offer our customers the highest metal stamping quality and highest level of customer service.

From single blanking operations to complex progressive dies, Norlen's stamping department provides a quality product with competitive prices. Skilled operators and tool builders work side by side using the following capabilities:

- 60-440 Ton Capacity

- Progressive Die

- Hand Transfer

- Automation

- Robotic transfer

- Assembly in die

- Automated scrap removal system

- Centralized lubrication system

- QDC for efficient change over

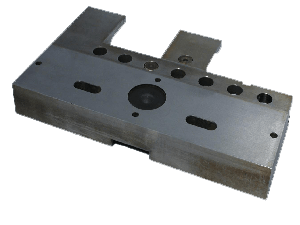

Tooling

Norlen continues to build on its position as a respected industry leader in tooling, by quickly recognizing our customer's needs and offering the best possible solutions.

Norlen's tool room provides the skill and technology necessary to support the manufacturing needs of the company and its customers. Our design and build capabilities, preventive maintenance programs, and state-of-the-art sensoring are combined to create a very productive environment centered around continuous improvement.

We support our customer manufacturing needs by using our in-house Die Sensor programs which includes:

- Analog and Digital Technology

- Investment Protection

- In-Die Assembly and Transfer System

- Analog Technology for Part Inspection

- 3D EDM Tool, Fixture Design and Build